Cooling and Heating, Temperature control for EV/HEV Automotive

Currently, a major bottle-neck for EV development comes from battery and motor issues.

Besides that, the thermal management issues for each of the electric components is also of major importance. Fortunately, LEA’s Al vapor chamber heat-sinks and Thermoelectric Vapor Chamber system offers excellent thermal solutions for the following.

Heat exchangers for inside of the vehicle

- High-power LED headlamp

- IGBT module for Inverter / converter

- Junction boxes, battery packs

- PCU(power control unit)…etc

- For charging stations: Inverter

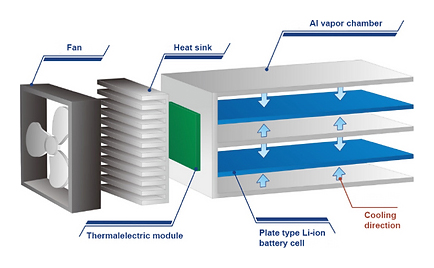

TVC Temperature Control System for EV/HEV Battery Management

“Features”

- Easy to maintain module type system

- An integrated system that has both cooling and heating functions, along with high-cost performance

- High uniformity temperature distribution

- *Precise Temperature control(<+/-2℃)

“Application”

The TVC is a battery temperature control system. Done by our specialized combination of the Peltier module and the aluminum vapor chamber.

“Cooling”

When the Peltier module is turned on, low temperatures are transferred via the vapor chamber in order to directly cool the battery cell.

“Heating”

Changing the current of the Peltier module switches it to produce heat. Heat is then transferred via the vapor chamber, thus warming up the battery cell.

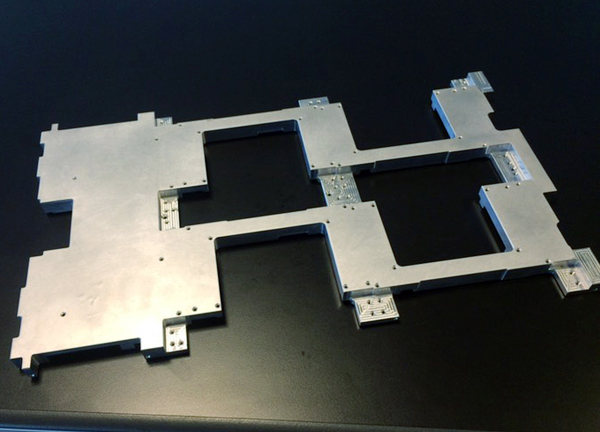

Lithium-ion battery heat dissipation vapor chamber

“Features”

- Large size aluminum vapor chamber

- 8℃ Temperature difference within

“Application”

The world’s first aluminum vapor chamber with a length of more than 1m. This VC is placed directly on the lithium-ion battery according to the width of the electric vehicle battery pack. Thus, it is used as a direct heat dissipating method.

“Specification”

- Product No.:J0020201006-01

- Dimensions :L1,199mmxW182mmxD10mm

- Weight:2,300g